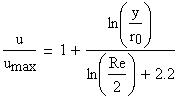

In this case (round pipe flow) control authority would

be limited by 4-5%.

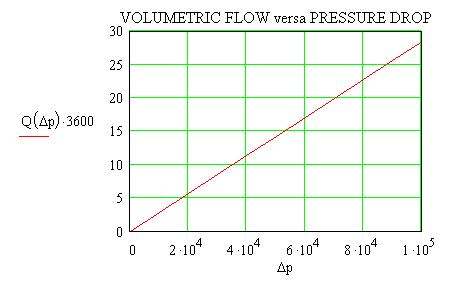

However, in assumption that the DPZTFFC will change

interaction between flow and wall surface we can change

the velocity to make flow turbulent earlier. For example,

for pipe with 10 mm dia. and water as media Re~10^4*V

and critical velocity is 0.2 m/sec. Presumably the

DPZTFFC could make the critical velocity smaller.

In this case ( laminar / turbulent flow transfer) control

authority would be 50-80% of flow.